Concrete Crossing

What We Do

DESIGN

An Omni engineer will evaluate and design a crossing for the application

MANUFACTURER

Omni manufactures all products at their McHenry, Il plant. Houston, Tx, Lincolnton, NC plants manufactuers concrete products.

WARRANTY

Omni Products exclusive warranty guarantees the railroad grade cossing will be free of manufacturing defects for six years.

Embedded Concrete-Rubber (ECR)

ECR is the fastest and easiest concrete crossing system to install because of its unique integrated concrete-rubber design.

As with all concrete systems, a well constructed foundation and track structure will ensure optimum life and performance. ECR is suitable for most traffic conditions.

Embedded Concrete-Rubber (ECR) Specifications:

Cross-Section View

Panel Lengths:

- 8′, 8′-1 1/2″, 9′ and 10′

Panel Height:

- Accomdates 115# to 141# Rail

Gauge Panel Width:

- 50 1/2 inches

Field Panel Width:

- 27 inches (10-foot tie)

- 21 inches ( 9-foot tie)

Concrete:

- Compressive Strength: 6000 p.s.i. Min.

- Entrained Air: 6.0 % ± 1%

- Max. Water/Cement Ratio: 0.44

- Salt Sealer: Co-Ma-Seal CM

Rebar:

- ASTM A615 Gr.60 (Tied)

- ASTM A706 Gr.60 (Welded)

Steel Angle:

- ASTM A36

Field Rubber:

- Type: Virgin SBR

- Tensile: 2,000 p.s.i.

- Hardness: 65 ± 5 Durometer Shore A

- Elongation: 400%

Gauge Rubber::

- Type: EPDM

- Tensile: 850 p.s.i.

- Hardness: 75 ± 5 Durometer Shore A

- Elongation: 400%

Fasteners:

- Timber Screws, 3/4″ x 12″

- Medium Carbon Steel.

- Tensile Strength 120,000 psi Min.

- Pullout Resistance +13,000 lbs

Improved-Concrete (IC)

Improved-Conrete Specifications:

Improved-Concrete Cross-Section:

Panel Lengths:

- 9′

Panel Heights:

- Accomdates 115# to 141# Rail

Gauge Panel Width:

- 43 1/2 inches

Field Panel Width:

- 22 3/8 inches (10-foot tie)

- 16 3/8 inches ( 9-foot tie)

Rubber Railseal Widths:

- 6 1/2 inches (Gauge)

- 6 3/4 inches (Field)

Concrete:

- Compressive Strength: 6000 p.s.i. Min.

- Entrained Air: 6.0 % ± 1%

- Max. Water/Cement Ratio: 0.44

- Salt Sealer: Co-Ma-Seal CM

Rebar:

- ASTM A615 Gr.60 (Tied)

- ASTM A706 Gr.60 (Welded)

Steel Angle:

- ASTM A36

Rubber Railseal:

- Type: Virgin SBR

- Tensile: 2,000 p.s.i.

- Hardness: 65 ± 5 Durometer Shore A

- Elongation: 400%

Fasteners:

- Timber Screws, 3/4″ x 12″

- Medium Carbon Steel

- Tensile Strength 120,000 psi Min.

- Pullout Resistance +13,000 lbs

TraCast™

A continuous protective rubber rail boot insulates the rail from electrical interference. RailGuard™ rubber panels are installed on the gauge side of the rails to provide a positive flangeway and rail cushioning. The RailGuard™ rubber panels can be easily removed with a lining bar, eliminating the need of heavy equipment, for rail inspection and repair.

TraCast Specifications:

TraCast Cross-Section View:

TraCast™ Module.

- Length: 6 feet

- Height: 13 1/4 inches

- Width: 7 feet 11 inches

- Weight: 7000 pounds

- Accomodates: 115# to 136# Rail

Rebar

- ASTM A615 (Tied)

Concrete

- Compressive Strength: 6,000 psi

- Entrained Air: 6.0% ± 1%

- Max Water/Cement Ratio: 0.44

- Salt Sealer: Co-Ma-Seal CM

Lifting

- Four 2-ton embedded lifting hooks

- Attach to 4-way rigging

RailGuard

- Type: Virgin SBR

- Tensile: 2,000 p.s.i.

- Hardness: 65 ± 5 Durometer Shore A

- Elongation: 400%

Protective Rubber Rail Boot

- Type: Santoprene™

- Tensile: 1,600 p.s.i.

- Hardness: 80 ± 5 Durometer Shore A

- Elongation: 400%

- Volume Resistivity: 1 x 1012 (min)

GripTite Cone Nuts

- Used to Anchor RailGuard Rubber Panels

- Material: Polyurethane

Rail Fastening

- Spring Clip: FLEXICLIP, 1095 Steel

- Spring Clip Insulator: Type I, Dupont Zytel

- Hex Head Bolt: 3/4-inch NC

TraCast 2™

The OMNI TraCast 2™ grade crossing design is a system of precast concretemodules with a minimum compressive strength of 6000 psi. Elastic fasteners are used to secure the rail to the base of the rail troughs. The module design eliminates the use of ties and ballast.

A continuous protective rubber rail boot insulates the rail from electrical interference. RailGuard™ rubber panels are installed on the gauge and field sides of the rails to provide a positive flangeway and rail cushioning. The RailGuard™ rubber panels can be easily removed with a lining bar,eliminating the need of heavy equipment, for rail inspection and repair.

OMNI’s TraCast 2™ system is ideal for highway, industrial, port, and transit use.

TraCast 2 Specifications:

TraCast 2 Cross-Section View:

TraCast 2™ Module.

- Length: 6 feet

- Height: 13 1/4 inches

- Width: 8 feet 3 inches

- Weight: 7,000 pounds

- Accomodates: 115# to 136# Rail.

Rebar

- ASTM A615 (Tied)

Concrete

- Compressive Strength: 6,000 psi

- Entrained Air: 6.0% ± 1%

- Max Water/Cement Ratio: 0.44

- Salt Sealer: Co-Ma-Seal CM

Lifting

- Four 2-ton embedded lifting hooks

- Attach to 4-way rigging

RailGuard

- Type: Virgin SBR

- Tensile: 2,000 p.s.i.

- Hardness: 65 ± 5 Durometer Shore A

- Elongation: 400%

Protective Rubber Rail Boot

- Type: Santoprene™

- Tensile: 1,600 p.s.i.

- Hardness: 80 ± 5 Durometer

- Shore A

- Elongation: 400%

- Volume Resistivity: 1 x 1012 (min)

GripTite Cone Nuts

- Used to Anchor RailGuard Rubber Panels

- Material: Polyurethane

Rail Fastening

- Spring Clip: FLEXICLIP, 1095 Steel

- Spring Clip Insulator: Type I, Dupont Zytel

- Hex Head Bolt: 3/4-inch NC

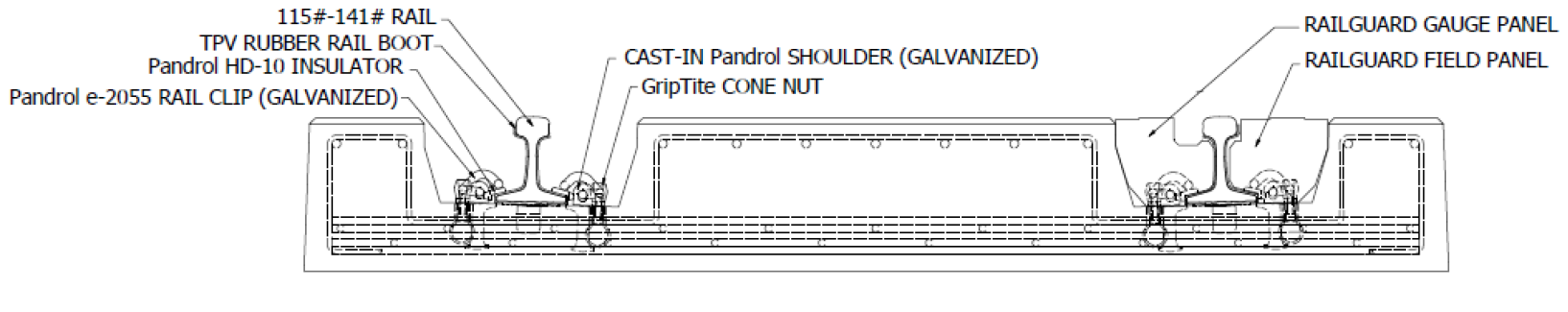

TraCast3™

The OMNI TraCast 3™ grade crossing design is a system of precast concrete modules with a minimum compressive strength of 6000 psi. Elastic fasteners are used to secure the rail to the base of the rail troughs. The module design eliminates the use of ties and ballast.

A continuous protective rubber rail boot insulates the rail from electrical interference. RailGuard™ rubber panels are installed on the gauge and field sides of the rails to provide a positive flangeway and rail cushioning. The RailGuard™ rubber panels can be easily removed with a lining bar, eliminating the need of heavy equipment, for rail inspection and repair.

OMNl’s TraCast 3™ system is ideal for highway, industrial, port, and transit use.

TraCast3 Specifications:

TraCast3 Cross-Section View: